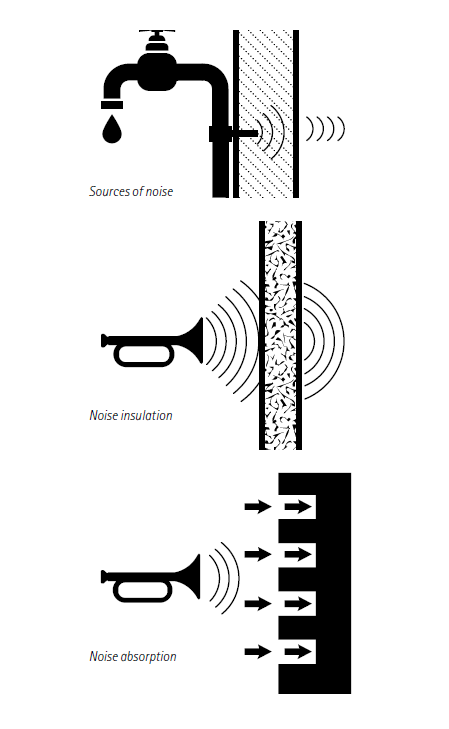

Pipe work systems installed for fluid supply, heating and sanitary purposes, as well as ductwork systems for air conditioning, can act as conductors of acoustic vibrations. These vibrations arise from the flow of the medium in the system, the method of system connection and pumps, fans, valves etc.

If a system conducting the acoustic vibrations mentioned above is directly fixed to walls or ceilings the noise level can increase because the building structure acts as an amplifier. Building regulations state a maximum permissible transmitted noise level from pipe work systems (see DIN 4109). Currently this residual valve is 35 dB (A) future regulation is expected to reduce this level.

To reduce the transmission of acoustic vibrations in pipe work to the building structure, a layer of acoustic vibration absorbing material must be placed between the pipe work and all support

fixing points. It is essential that the support fixing point into the building structure is never directly in contact with the pipe work. The smallest direct contact will act as a sound carrying bridge. Therefore, the acoustic vibration absorbing material needs to be specifically designed for each pipe clamp support.

The acoustic vibration absorbing materials used in our products are rubber profiles. Since rubber is elastic the transmission of acoustic vibrations is considerably reduced. The shape of the rubber profile is specifically designed for each clamp to eliminate contact between pipe and clamp. We have also paid considerable attention to the cross section of the rubber profile by introducing grooves which maximize absorption of acoustic vibrations.

The rubber lining must be durable and capable of retaining its elastic qualities to adequately absorb acoustic vibrations over a prolonged period. In consultation with rubber technology experts we have established performance standards to optimize aging resistance. The rubber profiles which we use are regularly tested against these performance standards independent specialist testing institutes.

The reduction in noise transmission by use of our rubber lined pipe clamps tested by independent institutes on the basis of the requirements of DIN 4109. The test method employed is that described in DIN 52 218 for measurement of noise transmission reduction of rubber linings.

Original test certificates are available upon request.

Please note the recorded RESIDUAL VALUE of noise transmission is that achieved by the DIN 52 218 test and measurement method at 3 bar.

EPDM rubber (both black and green) has been designed for an operating temperature range of minus 58° F up to plus 200° F, continuous. For a peak situation it can be plus 250° F. For steam pipes a special silicon rubber profile (red) is available, allowing for an operating temperature of 390° F, continuous and 420° F peak.