To select the correct isolator, you must have an overview of the vibration situation at hand. Below are some of the key external factors that should influence your selection

- Equipment specifications

You need to check the type of equipment to be isolated together with its dimensions, structural attachment points, and location within the building. Other considerations include the installation and foundation requirements as well as the specifications such as the bolt and hole sizes for securing the equipment.

- Location of equipment

You need to know where the machinery is located and what its structural support is. For example, is the equipment placed on a grade slab in a basement or on the top of the roof?

- Vibration excitation of the equipment

Rotational frequency forces and couples are important considerations here. The forces and couples caused by reciprocating masses can influence the isolation requirements.

- Type of building

The type and use of the building can have a significant impact on the choice of the isolator. Different building types like hospitals, apartment complexes, entertainment centres or industrial facilities are used for different purposes and consequently have different isolation requirements.

- Environmental considerations

Whether the equipment is placed indoors or outdoors can make a big difference, but under all circumstances, you need to consider environmental factors such as the degree of corrosivity and the minimum and maximum ambient temperature near the equipment.

- Special requirements

Last but not least, you need to check if there are any special requirements. Think about electrical, tubing, piping, or ducting connections that might modify the mechanical response of the mounting system. Other special requirements can include externally applied forces or moments; minimum or maximum clearance requirements between equipment and foundation; alignment requirements; or dynamic loads.

How to evaluate the suitability of an isolator?

Once you have a full overview of all the relevant environmental and external factors, you need to select the isolator that provides you with the most efficient solution. Vibration can be isolated or reduced to a fraction of the original force with isolators placed between the equipment and the supporting structure.

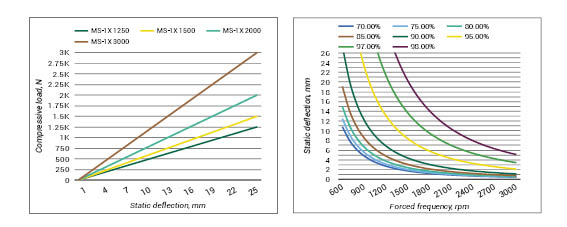

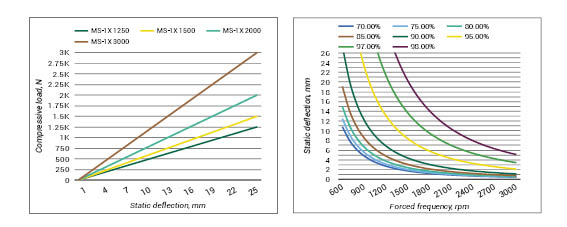

When it comes to the selection of an isolator, you need to look at three different values. These are the static deflection and the natural frequency of isolators together with the running frequency of equipment mounted on them.

Learn more about the anti-vibration solutions from Walraven

In the Walraven portfolio, you can find a complete range of rubber and metal vibroacoustic isolators of anti-vibration pads, mounts and springs to eliminate vibration problems in HVAC installations. The isolators can also be easily integrated with other typical pipe fixings, rail support or rooftop installations.

Read more