Why use Stainless Steel fixings?

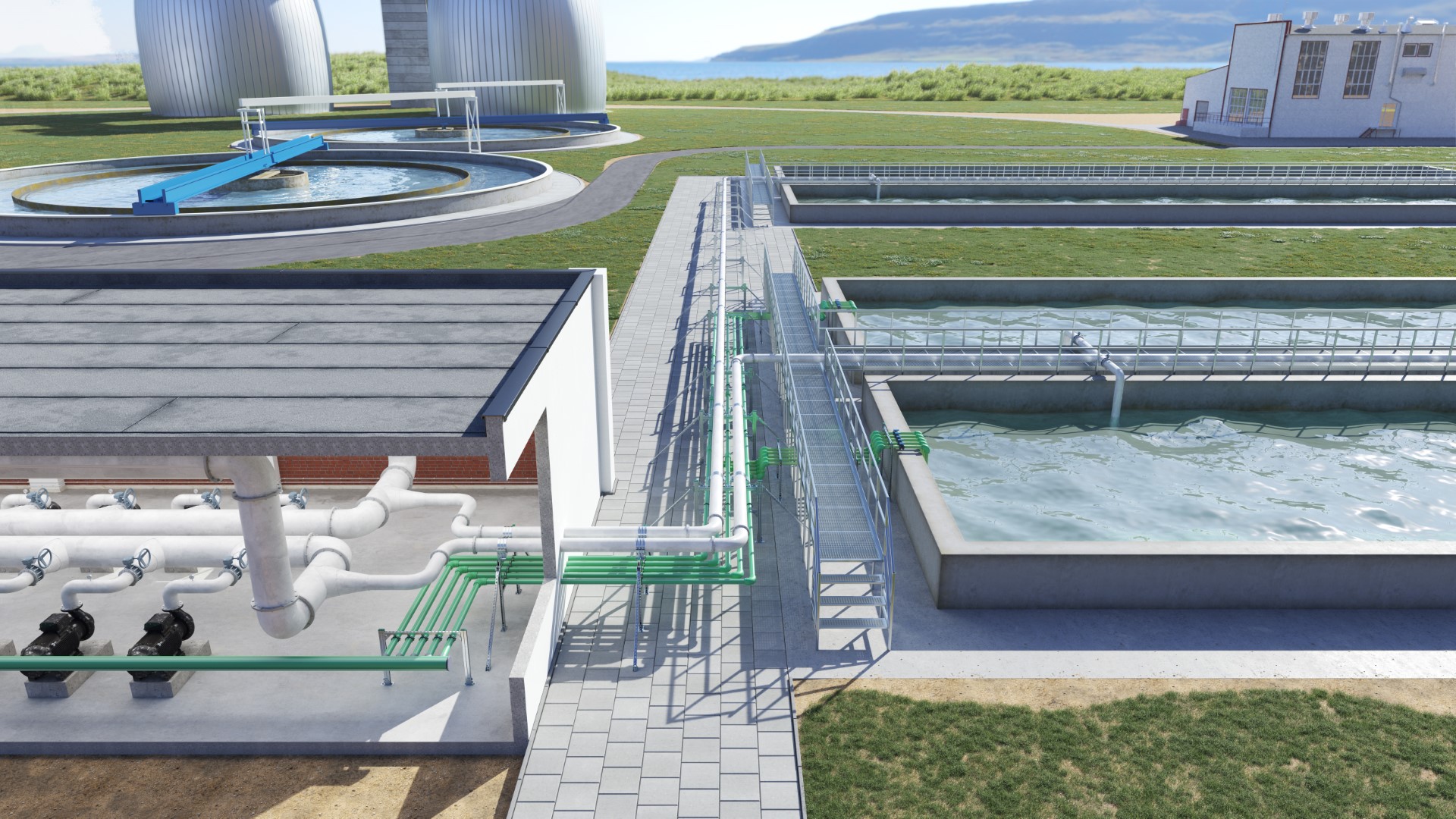

Stainless Steel has become a popular choice of product over the years, primarily thanks to its high corrosion resistance and aesthetic appeal. It is also very low maintenance and easy to clean making it suitable for applications where cleanliness and corrosion-resistance are key. For example, food and drink production plants, water treatment plants, pharmaceutical plants and so on.

The high corrosion resistance of the product is enabled by its high (over 11-12%) chromium content. Unlike regular carbon steel, when getting exposed to corrosive factors, the chromium layer of Stainless Steel starts oxidising instead of the steel itself. The oxidised chromium forms a very thin and tight layer which protects the metal from oxygen attacks.

A2 vs A4 Stainless Steel

The two most commonly produced grades of Stainless Steel are 304 (also known as A2) and 316 (also known as A4). Even though they share a lot in common, there are some fundamental differences between the two. Please see table below for more guidance.

| Comparaison | A2 Grade | A4 grade |

|---|---|---|

| Resistance to chemicals | Not resistant to chemicals, and it can even react sensitively to ordinary household detergents | Resistant to aggressive chemicals |

| Material composition | 18% chromium and 8% nickel content | >18% chromium, >8% nickel+ 3% of molybdenum content |

| Hygiene | A2 grade is recommended for areas with low and moderate pollution and only ordinary hygiene requirements | For areas with high hygiene criteria, for example food production, the use of A4 grade is mandatory |

| Corrosion resistance | Limited resistance, only for areas with low and moderate pollution. The A2 grade is not recommended to be applied near salt-water, marine and coastal areas | Very high corrosion resistance. Even resistance in areas with high pollution and salt content |

| Cleaning | Recommended to be cleaned by clean water only. Chemicals and detergents can cause impairments in the functioning of the metal | Recommended to be cleaned by clean water only. Chemicals and detergents can cause impairments in the functioning of the metal |

Why bother about corrosion and surface protection?

Corrosion refers to the physico-chemical interaction between the metallic material and its environment. It is important to realise that this interaction can result in changes in the properties of the metal, and this may lead to significant impairments in its performance.

To avoid changes in the properties of the metal, one needs to be mindful about selecting the right surface protection material. This primarily depends on the presence and concentration of corrosion factors in the environment. After identifying the most relevant corrosion factors, it is recommended to take the guidance as defined by EN ISO 14713 on which surface protection method suits your environment best.

| Applications* | Corrosivity class** | Zinc coating | Hot dip galvanized | Hot dip galvanized | Stainless Steel |

|---|---|---|---|---|---|

| Dry indoor spaces | C1, C2 | ||||

| Indoor spaces with occasional condensation | C1, C2 | ||||

| Outdoor areas with low pollution | C2, C3 | ||||

| Outdoor areas with moderate pollution | C3, C4 | ||||

| Coastal areas | C4, C5, CX | ||||

| Outdoor areas with heavy pollution | C4, C5, CX | ||||

| Extreme/special applications | Please consult us for more information |

||||

* Please consider the content of the table as guidance over explicit recommendation for a certain material or product

** According to EN ISO 14713

*** BUP (Walraven BIS UltraProtect 1000) can be used depending on your environment. Please consult us for more information

The Walraven offer

With over 80 years of experience in the installation and surface protection market, we understand the complexity of selecting the right materials and assessing the corrosion factors in the field. To this end, next to various surface protection options, we offer a complete and fully A4 graded range of Stainless Steel product portfolio suitable for the most typical application areas.

With our customer-oriented logistics concept, we ensure prompt delivery, which can even happen within a week. Furthermore, upon request, we also support with the design, calculation and the prefabrication of the system.

Contact us

Do you have questions relating to Stainless Steel or would like to get support with your next project?

Please contact us

Or visit our international website.

Or visit our international website.