It is natural for materials to expand in the heat and contract in the cold, and pipes are not immune to nature’s laws. Thermal expansion and contraction of pipework are some of the largest dynamic forces acting upon piped services.

Because piping systems often carry hot fluids, thermal expansion and the associated stresses must be carefully considered to avoid problems. The forces created by the thermal expansion can be large enough to cause pipe bowing and buckling, damaged pumps, valves, pipe clamps and fixings and even fracturing of the pipe or damage to the steel or concrete structure of the building.

In this blog, we will take a look at some of the factors that need considering when dealing with thermal pipe expansion, and also look at the basics of how to calculate the rate of thermal expansion within pipe systems, which is crucial to working out what products are required to deal with the problem.

But first, here is a video that illustrates just how significant thermal expansion can be.

Temperature changes cause an object or substance to change shape, area or volume. Pipes will generally expand when heated and contract when cooled. This is caused by the molecular structure expanding due to the increased kinetic energy at a higher temperature – causing the molecules to move around more.

The rate of thermal expansion usually depends on three key factors:

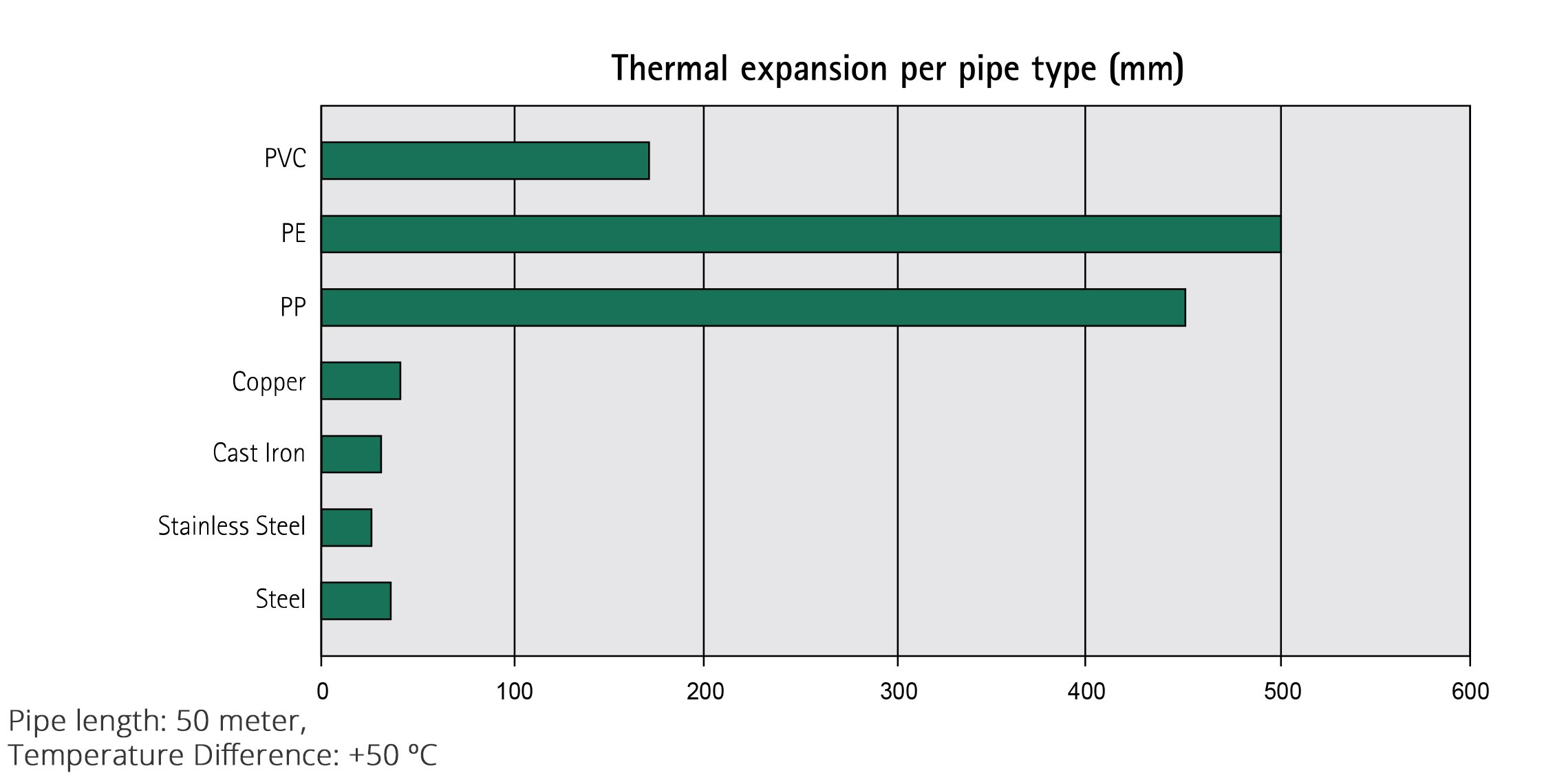

The chart below gives an example of expansion rates for 50-metre pipes with a temperature differential of +50°. As you can see, plastic pipe types usually expand significantly more than metal pipe types. For example, a 50m PE pipe with a +50° temperature differential will expand by 500mm.

It is crucial that the expansion and contraction of pipework are addressed at the project’s design stage to avoid significant problems.

Problems such as snaking pipes or stress on pipe joints could eventually lead to leaks or burst pipes and all the related damage that a failure could cause.

So, what are the solutions for dealing with thermal pipe expansion?

The expansion and contraction of the pipe can usually be accommodated in two ways:

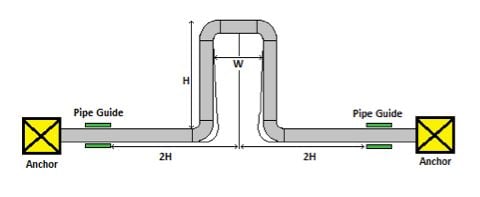

It is often preferable to accommodate the expansion in a natural way using expansion loops, as expansion joints add considerable force into the pipe system. Expansion loops accommodate thermal movements by installing sections of piping that run perpendicular to the piping system. Although these loops are semi-rigid, they do allow for some movement, thus reducing stress loads on the anchor points in the piping system. A fixing point is used to ensure that the expansion is directed to the expansion loop where the force and movement are controlled.

The pipe fixings or ‘guides’ between the fixing point and the expansion loop only guide the pipe in the right direction. When an expansion loop is being used, the distance between the first guiding clamp and the loop is important. The smaller the distance, the larger the force will be to bend the pipe. This force is transferred to the fixing point.

Expansion loops can take up a lot of room in the piping system layout, so they are most often used in outdoor systems. In more confined spaces, flexible loops can be made which use corrugated metal hose assemblies for each leg of the loop. These flexible loops are more compact than pipe loops but require structural supports to prevent sagging. These kinds of loops are typically used where seismic protection is required.

If there is no room for an expansion loop, then an expansion joint capable of axial movement should be used. An example of such a product would be the expansion bellows.

When an expansion joint is being used, consideration must be given to the pressure in the pipe. For example, a standard 200NB pipe with axial bellows creates over 2.5 tons of force. The pipe is kept aligned, but huge forces are imparted in other areas.

As a result of the huge forces created, a good anchor point is essential to allow a bellows system to work effectively. A bellows system can still fail if incorrectly supported and installed along the entire piping system.

Simple rules can be followed to ensure effective installation of a bellows system with the use of primary guides and anchors.

Anchor Point

2nd Guide 14x pipe Dia

1st Guide 4x pipe

Dia

Bellows

1st Guide 4x pipe

Dia

2nd Guide 14x pipe Dia

Anchor Point

Sometimes designs can be over-engineered and still fail if fundamental principles are not applied. Designs should be kept simple and follow the basic design rules mentioned above. The below design is a simple and effective solution.

Firstly, and most importantly, you need to be able to calculate the coefficient of thermal expansion for your piping system, to be able to determine the best solution for your needs. We have created a download to enable you to calculate the rate of expansion on your pipe. It includes the calculation method and some examples.

Download Walraven thermal expansion calculation information

Our Technical Support Team can assist you with making the calculations if required and can design a suitable support system for you to install.

We have products to assist you in installing expansion loops and bellows, including: