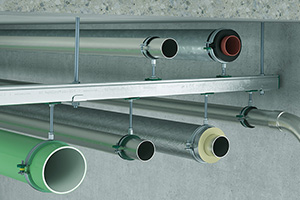

When fitting HVAC or sanitary installations, there are a number of factors to take into account before deciding on the fixings that you need. For example, pipes will expand and contract due to temperature changes and therefore require suitable fixings. The pipe clamps are the first elements to tackle the forces generated from expansion in the total fixing system: via the clamp through the threaded rods and rail constructions up to the fixing into the ceiling or walls. Secure fixing of the pipe all starts by choosing the right clamp.

When fitting HVAC or sanitary installations, there are a number of factors to take into account before deciding on the fixings that you need. For example, pipes will expand and contract due to temperature changes and therefore require suitable fixings. The pipe clamps are the first elements to tackle the forces generated from expansion in the total fixing system: via the clamp through the threaded rods and rail constructions up to the fixing into the ceiling or walls. Secure fixing of the pipe all starts by choosing the right clamp.

With the new and improved Walraven Light 2-Screw clamps, it becomes easier to choose the right solution for your residential, public or industrial project. The design of the installation and the choice of pipe material dictate your pipe clamp requirements. Whether the pipe is steel, copper or plastic, Walraven’s Light 2-Screw clamps offer a suitable solution.

The following factors need to be considered when selecting the right clamp for your needs. The Walraven Light 2-Screw clamp ranges have been designed with these considerations in mind. Here we tell you how the Light 2-Screw clamps are designed to deal with each variable:

Temperature:

Temperature:

The standard temperature range of -30 up to + 120 °C, the pipe’s expansion is influenced by the temperature of the medium.

Maximum load:

Maximum load:

All pipe clamps have been submitted to safe load tests. The specified maximum allowed loads (Fa,z), according to RAL-GZ 655/B, are calculated using specific statistical methods related to the breaking load and taking into account a deflection of 1.5mm or 2% of the maximum nominal clamp diameter.

Pipe material:

Pipe material:

The pipe material will affect the severity of the reaction to temperature changes. There are many types of plastic and metal pipe materials: PE, PVC, PP, Steel, Copper, Cast Iron, etcetera. Each has, among other things, different temperature resistance and also different resistance levels to chemicals such as oils, greases, acids, and chlorine. This affects what type of clamp should be used. For example, The lined Walraven Bifix® 5000 G2 clamp should be used for plastic pipes. An unlined galvanized steel clamp should not be used to mount a copper pipe as it can lead to corrosion.

Size:

Size:

The inner side size of the clamp is based on the outer diameter of the pipe. Some of our clamps, like the Walraven Bifix® 5000 G2, allow the pipe to slide freely through the clamp in case of expansion/contraction due to temperature differences. By removing the distance washers from the clamp before mounting it, you can also make the clamp suitable for tight fixing. Based on standard pipe diameters, the Walraven 2-screw clamps cover up to 225mm of all pipe sizes.

Environment:

Environment:

The environment into which your pipes will be installed affects your choice of clamps. Internal? External? Exposed to severe weather in coastal environments? It is an important consideration and will more than likely require a pipe clamp with a special coating for corrosion resistance, such as the Walraven Bifix® G2 range.

Special requirements:

Special requirements:

Some construction projects can have special requirements such as noise insulation or fast installation needs. Many of the 2-Screw lined clamps have certified levels of sound insulation (DIN4109 / -18dB(A)) as well as fast-fit features.

Do you want more general information about our pipe clamp range or our new and improved Walraven Light 2-Screw clamps? Or can we help you determine and planning the most effective fixing system for your pipe installations? Please feel free to contact us to discuss this with our experts. Our technical engineers have many years of experience with technical challenges on pipe installations and are happy to advise you. Don’t hesitate to get in touch!