For our client, a company specialising in implementing installation solutions for industrial and production facilities, we prepared a vibration isolation solution for an ammonia compressor with an operating weight of 14 tons.

To achieve the best level of vibration isolation, around 98%, spring-based solutions with a deflection value of up to 20mm must be used. As the unit’s centre of mass is not its geometric centre, calculations had to be made to determine the loads from all 6 fixing points, allowing a different spring to be selected for each.

The rationale for using spring vibration isolation under equipment having large vibrating masses (e.g. pumps, fans, combustion engines) is:

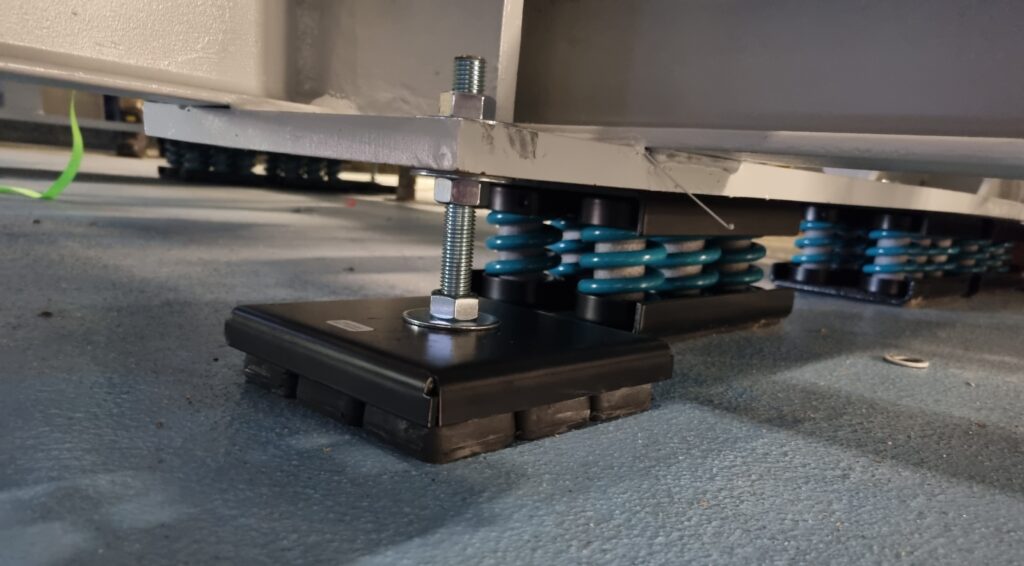

The solution prepared assumed special 6-spring packages designed and prepared individually for this case.

Due to the slenderness of the unit and the high suspended centre of mass, it was necessary, in addition to the spring vibration isolation, to use additional EPDM vibration isolators – which do not carry the weight of the unit but compensate for the deflection of the unit, standard to a spring-based foundation.