It can initially appear a simple task to install and fix pipes in an efficient manner. But there can be complexities which means you must be sure to calculate the right distance between your pipe clamp fixing points on each job you do, to ensure the integrity of the installation.

What are the rules to determine the distance between the brackets? There are no real guidelines or standards in the engineering sector. This means that installers have a degree of freedom. A pitfall of this freedom is that the distance between each pipe clamp is sometimes made too wide. This can mean, especially with plastic pipes, that the pipes start to bend.

An efficient way of installing is to combine different pipes, in diameter, material or even from another installation in one bracket support. As a rule of thumb the pipes with the shortest bracket distance (by diameter or material) determine the distance used.

But what is the maximum bracket distance?

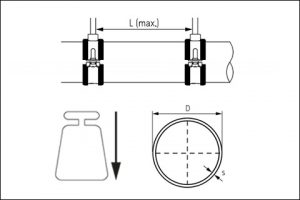

Pipe manufacturers almost always give a maximum permissible bracket (fixing) distance. This distance is determined by the combination of the material of which the pipe is made of, the diameter (larger diameter, stiffer pipe) and the weight of the pipe.

With steel pipes the bracket distance is generally permissible up to 6 metres. In practice, you rarely see this. An exception to this rule are long straight sections, because it is not practical to hang up a 6 metre pipe in one go.

Another major point is that you have to calculate the weight of the 6 metre pipe on the two brackets. This leads to heavy brackets and anchorages.

If your objective is to achieve maximum bracket distances, heavy duty pipe clamps can be a useful alternative to other standard clamps like split bands, to help you achieve this. The larger the bracket distance, the more force the pipe clamp and bracket will need to take. Using heavy duty clamps over other types of clamp can allow you to use larger distances as the HD clamps can take more force than other clamps.

We have produced our own tables of pipe dimensions and weights to help you determine the right bracket distance in different scenarios.

View Walraven’s pipe dimensions and weights tablesAs an installer, you are ultimately responsible for determining the appropriate bracket distance. You can do this based on your own experience or through reading the manufacturer’s documentation. You can also contact our technical advisers who can help you calculate the right fixing distances and provide tailored advice. Call us on 01295 753400 and ask for technical support, or email [email protected]