Walraven’s product designers have recently implemented a number of improvements to the original Walraven Maxx heavy profile system. As a result the system is now even easier to use, with improved corrosion protection.

Brand new Hammerfix connector allows faster installation and easier adjustments compared to when using screw or bolt fixings. The Hammerfix can be used for making all connections in the system. Find out more here.

All parts now HDG (hot dip galvanised) including the Hammerfix connector bolt, ensuring corrosion protection across the whole system (excluding the traditional bolt set).

Improved hole pattern design on all parts so that hole patterns line up perfectly when connecting parts together. Quicker, easier construction.

Improved base plate design including higher safe load performance as it is now made from a stronger steel (S275), and adjustments to the anchor holes for easy fixing with throughbolts.

Simplified system – removal of a few unnecessary parts means this system really is a simple modular kit which can be used for a multitude of MEP installations.

BIM objects will be made available for all parts soon.

You can view load values for the Walraven Maxx profile system in our Maxx Technical Data Sheet.

The key overall benefits of using a modular system mean you can construct heavy duty load-bearing frames quicker and safer than using traditional welded steel methods. They also offer increased flexibility, as the simple ‘kit’ formats can be used to construct a whole range of support types quickly and easily. The system can also be pre-assembled off-site.

The key overall benefits of using a modular system mean you can construct heavy duty load-bearing frames quicker and safer than using traditional welded steel methods. They also offer increased flexibility, as the simple ‘kit’ formats can be used to construct a whole range of support types quickly and easily. The system can also be pre-assembled off-site.

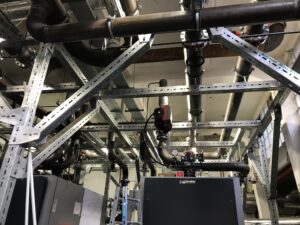

In building services heavy modular systems are used for plant rooms, pipe bridges, multi-service tunnels and more. They are so flexible and adaptable in their construction that they are becoming a popular choice for contractors looking to make efficient installations.

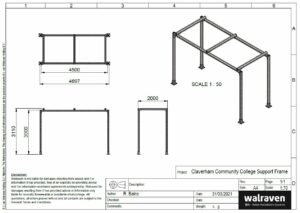

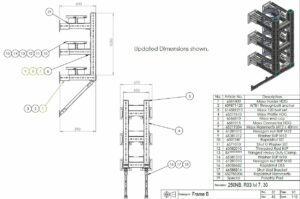

When you have a requirement for a heavy duty modular steel frame, our Technical Support Team can assist you with the design of a suitable support frame for your installation. We can analyse your installation environment and carry out calculations, analyse forces and other technical requirements in order to design an optimal solution.

Designs can range from really simple structures to more complex designs where required.

To read more about Walraven Maxx profile including product information, case studies and other useful articles click here.

If you would like to request a product demonstration or an appointment with a Walraven representative to find out more about this system then please complete the form on this page and we will get back to you. Alternatively you can request technical support here.

View Walraven Maxx profile product details