In a previous article, we explained what an ETA (European Technical Assessment) is and why it is so important for firestop products. In case you missed that article you can find a shortcut link to it here.

In a previous article, we explained what an ETA (European Technical Assessment) is and why it is so important for firestop products. In case you missed that article you can find a shortcut link to it here.

Here we will be giving you a step-by-step guide on how to navigate and read through ETA documents in order to find product performance that matches your project’s requirements. This can be invaluable for specifiers, designers or decision makers who need to come up with a firestopping solution.

For the purposes of this guide we will be using the Walraven Pacifyre MKII (P) as an example. This product is a fire sleeve approved for firestopping combustible pipes. Here is a link to the full ETA for this product.

The first part of the ETA document provides the reader with information on the product itself including a technical description, the parts it is made of and the intended use.

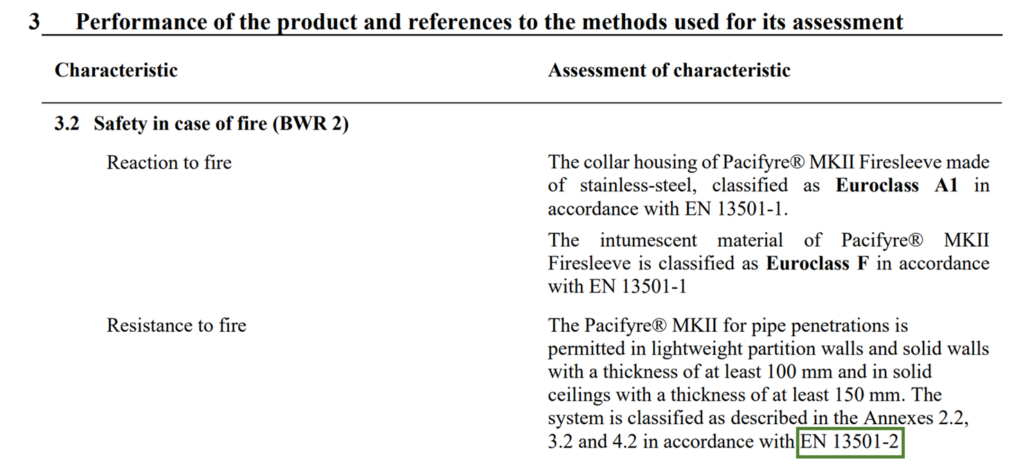

Furthermore, information is included about the methods applied for the assessment of the product’s performance. For example, in the extract below we can find information about the standard used to classify the MKII (P) for its fire resistance (in this case EN 13501-2).

Similarly, there are further assessments that can be carried out on a product such as air & water permeability, emission or release of dangerous substances, noise reduction and more. In conclusion, all assessments and standards that the product has been subjected to should be included in this first part of the ETA.

It will also detail the auditing system required for a particular product. This refers to how often the product itself will undergo audit to ensure its ETA and CE mark are kept up to date and still valid.

The second part of the ETA contains all the relevant and specific information regarding the use of the product and the performance expected according to different applications.

It is worth mentioning here that a firestopping product can only be used in configurations that it has actually been tested to and classified. Any other intended use outside the scope of the ETA must be consulted with the manufacturer who should be able to guide on best practise.

Fire sleeves and fire collars are all assessed on specific applications and these typically include firestopping pipes going through walls or floors. There are also different options regarding the base material itself and its composition, for example concrete, masonry or plasterboard wall etc. This information is crucial because a product’s performance may vary considerably when used in a wall as opposed to a floor.

Fire sleeves and fire collars are all assessed on specific applications and these typically include firestopping pipes going through walls or floors. There are also different options regarding the base material itself and its composition, for example concrete, masonry or plasterboard wall etc. This information is crucial because a product’s performance may vary considerably when used in a wall as opposed to a floor.

Likewise, performance of the product may be lower when it is used on flexible walls (stud wall) compared to rigid walls (concrete). This should be cross referenced to the ETA in order to determine the fire resistance obtained for each specific detail.

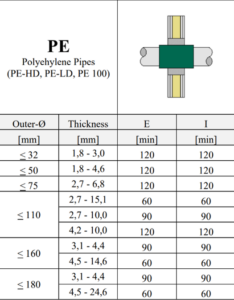

Another factor to be taken into consideration is the external size of the pipe. For example, in this table we can find the performance of the MKII (P) when it is used as a firestop seal for PE pipes that penetrate flexible walls.

Another factor to be taken into consideration is the external size of the pipe. For example, in this table we can find the performance of the MKII (P) when it is used as a firestop seal for PE pipes that penetrate flexible walls.

Performance is based on the external diameter of the pipe and it is assessed against Integrity (E) and Insulation (I). As you can see from the table, the larger the pipe the lower the maximum fire resistance the product can achieve. For a Ø160mm pipe a maximum 90min protection can be achieved as opposed to 120mins for smaller pipes.

This is something the designer needs to be aware of as there can be variations on the performance of the product depending on the pipe dimension, even though the same product and type of pipe is applied.

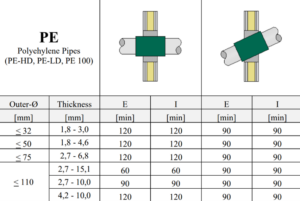

Another consideration when determining the performance of a fire sleeve and/or fire collar is the orientation of the penetrating pipe. Typically having pipes that penetrate a wall at an angle is a more onerous situation compared to a typical perpendicular penetration in regards to firestopping. This table allows you to compare the performance of the same product used on the same pipe but at a different angle. In this example, the maximum protection provided by the sleeve drops from 120mins to 90mins in most cases and this is something that needs to be taken into account when making a selection.

Another consideration when determining the performance of a fire sleeve and/or fire collar is the orientation of the penetrating pipe. Typically having pipes that penetrate a wall at an angle is a more onerous situation compared to a typical perpendicular penetration in regards to firestopping. This table allows you to compare the performance of the same product used on the same pipe but at a different angle. In this example, the maximum protection provided by the sleeve drops from 120mins to 90mins in most cases and this is something that needs to be taken into account when making a selection.

So far, we have seen examples of product performance on PE pipes, but what happens if we have plastic pipes of a different type such as PP, PVC, Multilayer etc? Can we still use the above tables? The simple answer is no and this is because each type of pipe must be assessed and classified independently. Within the ETA you should be able to find similar tables for different types of pipe material. If these are not present in the ETA you should be enquiring with the manufacturer for further information and guidance.

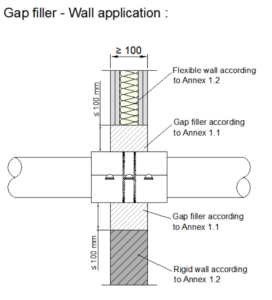

Every installation of a fire collar or a fire sleeve needs to be accompanied by an appropriate sealing system. Very often, this is only a small annular gap around the pipe that needs to be sealed in order for the system to achieve the fire resistance required.

Every installation of a fire collar or a fire sleeve needs to be accompanied by an appropriate sealing system. Very often, this is only a small annular gap around the pipe that needs to be sealed in order for the system to achieve the fire resistance required.

In such cases the use of an acrylic sealant might be enough, but there are more complex cases where the opening might be too big and the use of a fire batt is recommended.

In any case it is imperative to combine the installation of the collar/sleeve with an approved and tested sealant of the same manufacturer. Mixing products from different manufacturers is one of the most common mistakes that still takes place on sites and results in noncompliance.

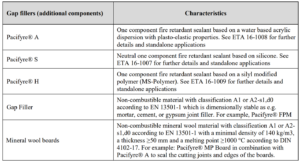

On the first image below we find the snapshot showing the construction detail that must be replicated on site where the fillers are referenced (Annex 1.1 for this particular example). On the second image we find the table with all the filling options (Annex 1.1.).

All the above information can be found on the same ETA document which makes specification of the correct system (not just product) a lot easier.

In conclusion, the ETA documents are a powerful tool for selecting the appropriate firestopping solution for the specific requirements that you have on your project. In this article we examined a case study of one of our products, the fire sleeve Walraven Pacifyre MKII (P). We walked through the information that is included within its ETA and we also discussed some key variations that can have an impact on the performance of the product (i.e. external dimension of pipes, substrate, orientation etc.)

The same thought process can be applied to any firestopping product in order to identify the appropriate firestop system (fire collar/sleeve together with any additional components such as fillers). This is critical because we cannot mix different products from different manufacturers and all components installed on site need to be installed as originally tested.

If you can’t find a specific detail that you are looking for, we strongly recommend getting in touch with the manufacturer and they should be able to guide you along the specification process.

In our following articles we will be exploring more criteria that need to be considered when specifying a fire stop solution for a pipe penetration, so stay tuned!

Get in touch with our fire stopping specialist. You can request a chat, discuss a current project or ask a specific question and will we do what we can to help you.

Read more firestopping articles