Turn down the volume of buildings

The operation of mechanical and electrical (M&E) services generates varying degrees of noise and vibration which, if left untreated, have the potential to cause damage to the equipment itself as well as to disturb occupants within a building.

The level of noise and vibration control required for M&E will often be specified by the acoustic consultant or noise and vibration engineer, with the specification determined by a number of factors, including:, Building Regulations, Noise at Work Regulations, employer requirements, building type, machine specifications.

Besides a complete range of vibration isolators, Walraven offers Technical Support and guidance to contractors installing vibration supports.

Learn more about vibration and how to prevent it

Effective noise and vibration control will help protect M&E equipment, which not only prolongs the life of the machinery it also reduces the cost and frequency of maintenance. Where noise and vibration are likely to cause a disturbance to building occupants, the objective of any M&E treatment is to prevent vibration from propagating into a building or stop airborne sound from transferring into occupied spaces and becoming nuisance noise. In many cases a combination of noise and vibration control solutions are required to achieve the specified performance levels.

Understanding the basics of vibration

Find out more about vibration of mechanical equipment and why it is important to prevent it.

Types of anti-vibration mounts

See an overview of the different types of vibration isolator for mechanical installations.

How to select the right vibration solution

There are a number of factors to consider when choosing an anti-vibration mount.

Where can you apply Walraven VibraTek® isolators?

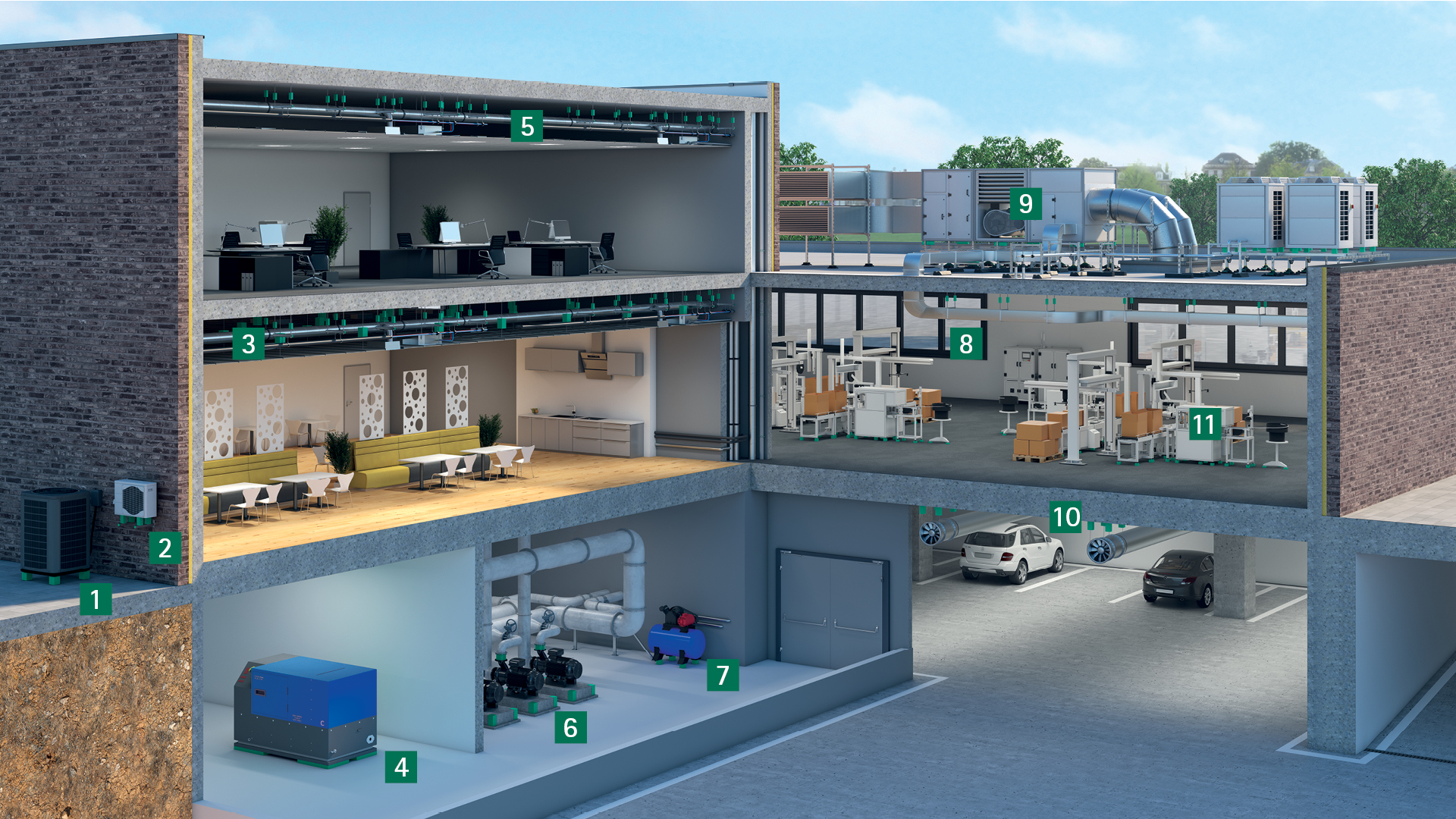

Here are some examples of applications where anti-vibration solutions may be required:

- Heat pumps

- Outside AC splits

- Acoustic ceilings

- Backup power generators and cogeneration plants

- Suspended piping system

- Pumps

- Compressors

- Ventilation ducts

- Rooftop chillers, refrigeration and air handling

- Inline fans and equipment

- Industrial processing machinery

Go to our online product catalogue to view the full range of Walraven VibraTek® solutions.

Walraven VibraTek® HS-1X Spring Hanger

- simple to install and does not need to be fixed to the base material

- recommended for machinery with low working speeds above 700 RPM

- epoxy powder-coated housing, cap and spring provide increased resistance to corrosion

Walraven VibraTek® MR-L 3000/M10 Rubber Levelling Mount

- recommended for machinery with working speeds above 2500 RPM, providing a degree of vibration insulation from 75% to 80%

- simple to install and does not need to be fixed to the supporting structure

- rubber isolator with DIN 934 nuts and DIN 9012 washers included in delivery for mounting and levelling equipment

Walraven VibraTek® MS-1X Spring Mount

- recommended for equipment with low working speeds, from 600 rpm and above

- epoxy powder-coated base, caps and springs provide increased resistance to corrosion

- flexible internal filler prevents debris and solid elements entering and damaging the spring under load

Walraven VibraTek® SB-MF Silentblock

- a universal rubber absorber, ideal for use with all kinds of elastic suspension or mounting of equipment

- ideal for use with machinery and equipment mounted on metallic surface

- for use in compression only

Browse the complete Walraven VibraTek®

Browse the complete Walraven VibraTek®

Or visit our international website.

Or visit our international website.