With ever-increasing demands on contractors to deliver projects quickly, cost-effectively, and environmentally friendly, it is not surprising they are now making more use of modular steel frame solutions.

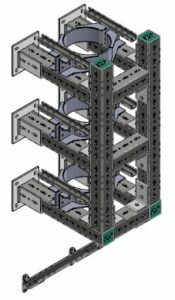

Modular steel frame systems like Walraven’s Maxx heavy frame system, are non-welded steelwork support systems. They allow for efficient fabrication of frames and load-bearing structures for building services.

Heavy frame systems like Walraven Maxx profile can be used for supporting loads that are beyond the capabilities of typical strut channel. These would previously have required traditional fabricated steelwork supports.

Modular systems can be delivered in three ways to suit your requirements:

Initially you might think that there would not be much of a requirement for a heavy steel system in building services, but there are a number of applications where standard strut products are not suitable for the job.

Traditionally, when this occurs, welded steel systems are used. But because of the benefits of modular systems previously mentioned, and the pressure for delivering projects faster and more efficiently, modular systems are growing in popularity for building services applications.

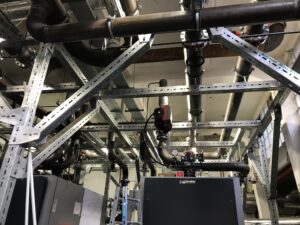

View our image gallery of building services installation examples using Walraven Maxx profile.

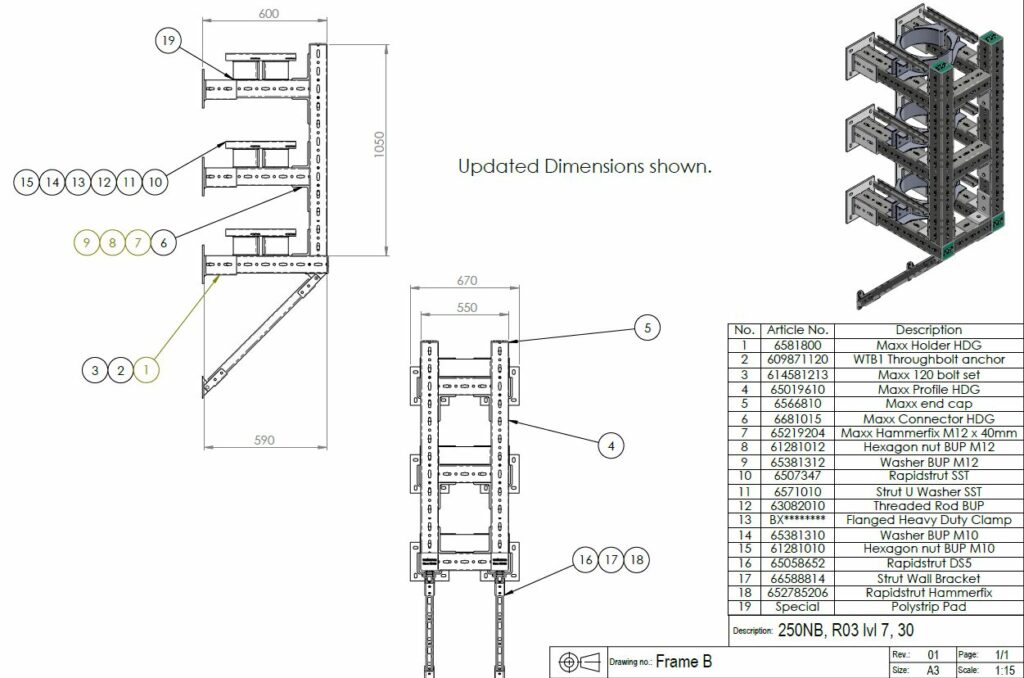

Our Technical Support Team can provide designs and part lists with loadings and all supporting calculations and documentation for your project. You will need to provide the specific details of your installation to enable us to deliver an initial design.

Find out more about Walraven Maxx profile including product information, case studies and other useful articles here.

If you would like to request a product demonstration or an appointment with a Walraven representative to find out more about this system, or request technical support then please complete the form on this page and we will get back to you.

View Walraven Maxx profile product range