A Danish chocolate and confectionery manufacturer invested in a modern production facility in Nowa Sól, Poland. The new plant will create about 130 new jobs for local residents and the Toms Group will systematically increase its activities in the city and employ more and more workers. In terms of the supply chain, Nowa Sól is an ideal location for the Toms Group. “2018 was the year where we took a giant leap in the transformation of our supply chain platform and initiated the construction of a new manufacturing plant in Nowa Sól,” said Carsten Lyngsø Thomsen, CEO of the Toms Group, 2018.

A Danish chocolate and confectionery manufacturer invested in a modern production facility in Nowa Sól, Poland. The new plant will create about 130 new jobs for local residents and the Toms Group will systematically increase its activities in the city and employ more and more workers. In terms of the supply chain, Nowa Sól is an ideal location for the Toms Group. “2018 was the year where we took a giant leap in the transformation of our supply chain platform and initiated the construction of a new manufacturing plant in Nowa Sól,” said Carsten Lyngsø Thomsen, CEO of the Toms Group, 2018.

The PM Group was appointed supervisor of the project. Their involvement began in 2016 with site selection, concept design development and site master-planning. It continued through basic and detailed design, procurement, construction management, supervision of the architect, commissioning and start-up assistance.

The project was recognized with a regional award from the National Labor Inspectorate for the high value placed on safety.

As you walk through a typical food processing plant, you can see equipment constructed of a myriad of materials, including carbon steel, aluminum, stainless steel and plastics. Corrosion can be an enemy of many of those materials. Because of the quality of food requirements, purity and sanitation standards require excellent corrosion resistance in the entire production area. These food quality requirements lead most plants to select stainless steel as a material of choice.

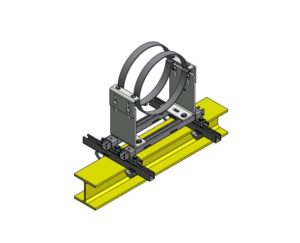

Our technical engineers worked closely with the main contractor and the installation subcontractor throughout the project to develop an effective and high quality support solution for the diverse pipe installations. Due to the corrosive environment around these installations, special consideration had to be given to the surface protection of the components. At first, only Stainless Steel A2 or A4 was allowed to be used. We convinced the investor and supervisor to recommend Walraven’s BIS UltraProtect® 1000 fixing system solution. This system consists of products treated with the special Walraven UltraProtect® 1000 coating. It withstands up to 1,000 hours salt spray test (according to ISO 9227), ensuring the best corrosion protection, making it suitable for industrial food environments.

Our technical engineers worked closely with the main contractor and the installation subcontractor throughout the project to develop an effective and high quality support solution for the diverse pipe installations. Due to the corrosive environment around these installations, special consideration had to be given to the surface protection of the components. At first, only Stainless Steel A2 or A4 was allowed to be used. We convinced the investor and supervisor to recommend Walraven’s BIS UltraProtect® 1000 fixing system solution. This system consists of products treated with the special Walraven UltraProtect® 1000 coating. It withstands up to 1,000 hours salt spray test (according to ISO 9227), ensuring the best corrosion protection, making it suitable for industrial food environments.

In addition to the topic of corrosion protection, our technical engineers also had to take the pipe expansion and contraction into account. If the behavior of the pipe, due to temperature differences, is not properly accounted for when installing the pipework, the movement of the pipe will damage the pipe support systems over time. Expansion devices were installed to allow for the linear thermal movement.

In addition to the topic of corrosion protection, our technical engineers also had to take the pipe expansion and contraction into account. If the behavior of the pipe, due to temperature differences, is not properly accounted for when installing the pipework, the movement of the pipe will damage the pipe support systems over time. Expansion devices were installed to allow for the linear thermal movement.

Our engineers were technically involved in the calculations and drawings and visited the construction site several times.

Type of installations:

Type of installations:

Products used:

If you need a flexible, effective and easy to install solution for supporting your pipework in highly corrosive environments, our Walraven Technical Engineers can provide a comprehensive project support service to help you design and deliver an effective solution. Call your Walraven Regional Sales Manager (RSM) and let us find a solution for your installation.