Walraven RapidStrut® channel system

The Walraven RapidStrut® channel system offers high speed and safe installation. It consists of various rail profiles and an extensive range of accessories for all medium applications.

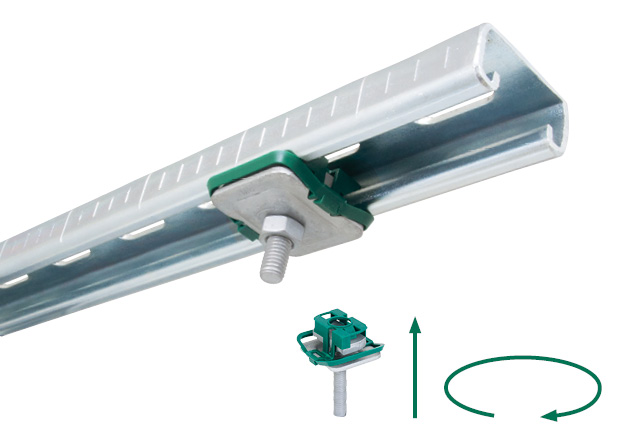

Insert, lock, done!

Walraven RapidStrut® channel accessories are pre-assembled and delivered ‘ready-to-use’ to the building site. For example, the plastic spring on the slide nut allows it to be fixed into the rail with one easy twist. The Walraven RapidStrut® channel system is so easy to use that it is possible to save up to 40% in fixing time!

Safety first!

All strut rails have inward-formed flanges with serrated profiles for extra grip. Together with the serrated design of slide nuts, it allows easy and safe positioning of accessories.

Also available with our Walraven BIS UltraProtect® 1000 finish!

As well as pre-galvanised and hot dip galvanised finishes, many parts of the Walraven RapidStrut® channel system are also available in our special Walraven BIS UltraProtect® 1000 finish which offers additional corrosion resistance of up to 1000 hours. This far exceeds hot dip galvanised (up to 600 hours) and zinc plated (up to 80 hours) products.

Features & Benefits

- Quick and safe installation

- Saves up to 40% fixing time!

- Accessories pre-assembled ‘ready-to-use’

- For all medium applications

- Also available with Walraven BIS UltraProtect® 1000 finish

Click here for an overview of all our Walraven RapidStrut® channel products

Back to medium fixing solutions

Walraven RapidStrut® channel product selection:

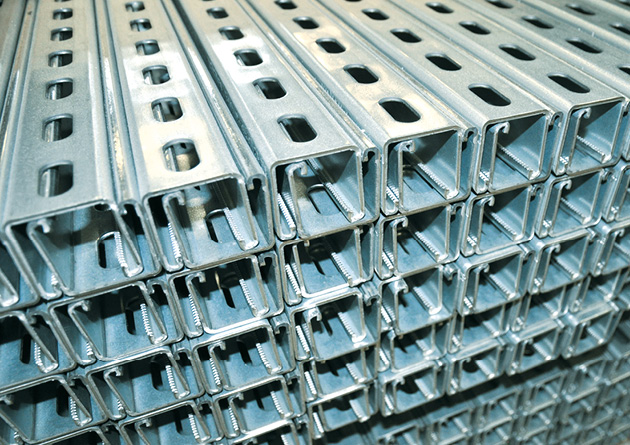

Walraven RapidStrut® Channel (pg)

- universal rail system

- distance between rail end and first hole is always equal

- inward formed flanges with serrated profile for extra grip

Walraven RapidStrut® Hammerfix G2 (BUP1000)

- slide nut with stud bolt, washer and BIS RapidStrut® spring

- ready-to-use pre-assembled for a quick fixing, and retains assembly in place before final tightening

- material: metal parts made of steel 1.0332; spring(s) made of POM (polyoxymethylene), green

Walraven RapidStrut® Cantilever Arm 41x41D (BUP1000)

- wall plate welded on Strut Profile

- slots at 90° to each other to simplify fixing

- CO

2 welded

Or visit our international website.

Or visit our international website.