IJburg is a large-scale urban development project on the outskirts of Amsterdam, the Netherlands. Where the territory of Amsterdam reaches the IJsselmeer, the biggest lake of the Netherlands, a major urban extension with a size of 220 ha and a population of more than 22.000 is being developed on artificial islands which have been raised from the lake. This means that the existing natural functions and requirements of the water system need to be taken into consideration in the development of the district. Both the first phase of IJburg and the second phase, in enhanced form, seek to work in harmony with the surroundings, an extraordinarily high density of up to 90 homes per hectare, ensuring the preservation of the quality of the water in the IJsselmeer, alongside a high aesthetic appeal. Because the development is on islands, which also have waterways cutting through them, then naturally water has to be a main consideration when developing the site.

Via Milder, producer and importer of plastic pipe systems, Walraven received the request to develop a pipe support system. For this project, ground-coupled heat exchanger systems were installed for residential use, and large-diameter PE pipe-work had to be constructed for the transportation of heat and cold water. Ground-coupled heat exchangers use the earth’s near-constant subterranean temperature too warm or cool the water, a viable and economical alternative or supplement to the conventional central heating in the properties of this project.

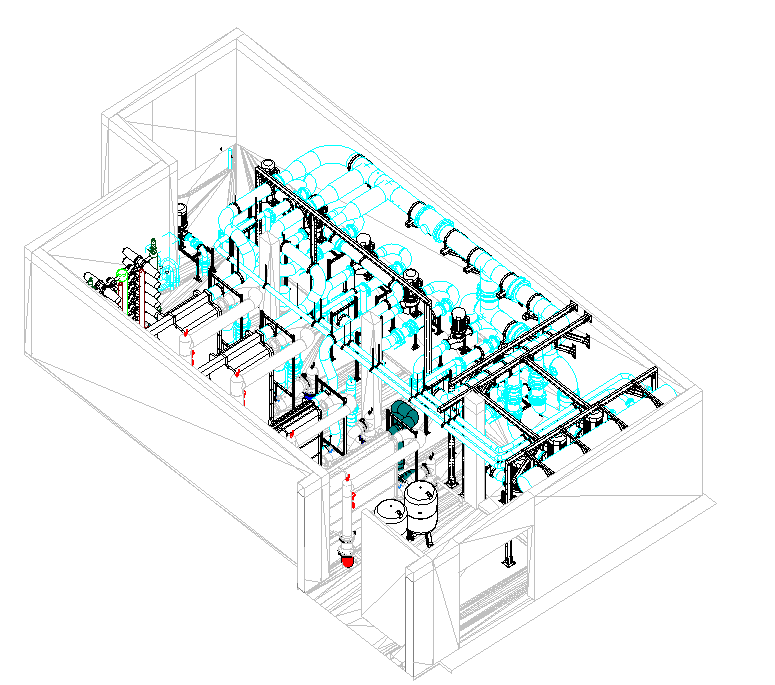

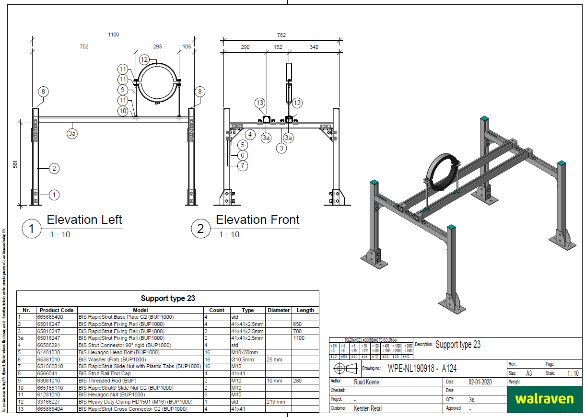

One of the main reasons why Kersten Retail, the main contractor of this project, selected Walraven as the supplier was that, besides their technical expertise, our technical engineers use Revit® software for their designs. Using Revit® software, our engineers produce consistent, coordinated and complete model-based designs and documentation. By using the integrated BIM specifying the Walraven products, they can develop effective and high-quality pipe support solutions for the diverse pipe installations and detect clashes on time. This not only results in safety and ease of use but also prevents waste, failure costs and expensive corrective measures. For the IJburg project, our engineers created the pipe support design in a separate Revit® file that linked to the master file that Kersten Retail sent to us, specifying the building- and installation design of the project. Once approved, the solution drawings were communicated to our in-house prefabrication service department for assembly. The design ensured fast and precise assembly, ensuring time and cost savings on-site.

Picture: Kees de Vries

Picture: Kees de Vries

Type of installation:

Products used (among others):

Would you like to find out more about how the Walraven pipe support systems could benefit your challenging projects? Why not get in touch to find out more? Request a call from your Walraven Regional Sales Manager (RSM) to discuss your requirements.