Pipes expand or shrink due to temperature differences. This could have serious consequences for the complete installation and cause damage to the entire building. We would like to explain this to you.

Each material (steel, copper, PE, PVC, etc) has its own specific coefficient for expansion. These coefficients determine how the various materials react to differences in temperature. Steel has an expansion coefficient of 0,012 mm/C° and PE an expansion coefficient of 0,200 mm/C°. In other words: a 10 metre steel pipe set with a temperature difference of 50 C° expands 0,6 mm. A PE pipe of 10 metres expands 10 mm. The expansion or shrinkage is not dependent on the diameter of the tube, but on the length and the material of the tube.

The expansion of the piping may cause nuisance in the form of sound (material stresses, the ticking of the old central heating pipes) and even damage to the building. This can often lead to pipes breaking which leads to water damage. Therefore it is wise to take this into account during installation.

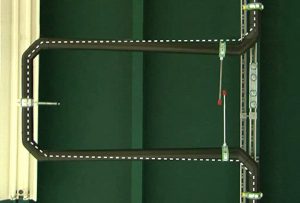

A good assessment of the installation (where to set the pipes and how many mm?) helps to create a good bracket plan. The very best solution is to allow the natural characteristics to work ‘freely’ as much as possible.

By placing afixed point in the right place, we can guide the expansion to this point to ensure no damage or stress can occur on installations. This way we can also minimize the released forces.

There is often no room for ‘nature’ to go its own way. Fixed and sliding points are engineered to make it a controlled expansion. We can also be of service for this.

Would you like to know more about preventing damage and noise pollution by/from expanding pipes? We have the knowledge and experience to help you. Our experts can calculate what the ideal installation method is for your project.